Synthetic fuels are considered the gateway to climate-neutral traffic. These ‘e-fuels’ are gaseous or liquid energy sources such as methane or diesel, which are used to replace fossil fuels. They are extracted from pre-existing CO2 in multiple stages; in this way their carbon footprint remains neutral – similarly to biofuels – although the greenhouse gas is then released into the atmosphere when driving.

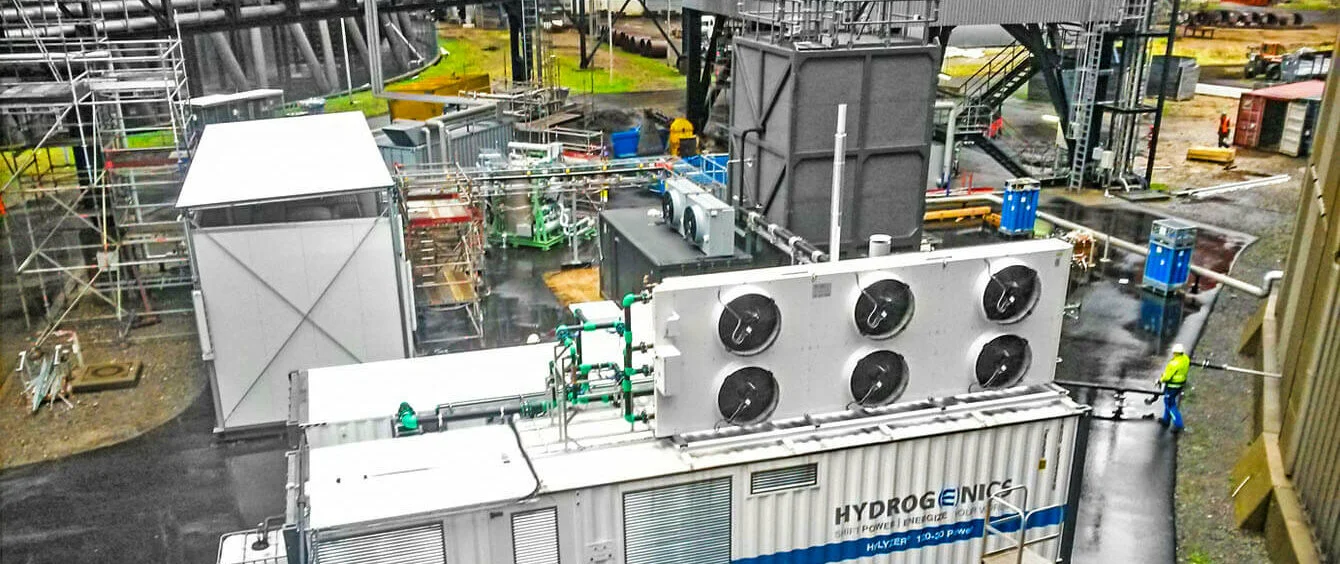

RWE has been ‘washing’ carbon dioxide extracted from the flue gas of the local Niederaussem power plant since 2009. The Essen-based power producer is now putting a new research facility into operation, which produces methanol from the extracted CO2. Nine partners from seven European countries are currently a part of the ‘MefCO2’ project – including industrial organisations, universities and research institutes. The European Union is backing the project with a total of 8.6 million euros in funding.

Fossil fuels are being replaced

In contrast to ethanol – commonly referred to as ‘alcohol’ – methanol (methyl alcohol) is not fit for human consumption. Nevertheless, it is a sought-after chemical, partly due to the fact that – similar to ethanol in E10 petrol – it can be blended with diesel fuels.

Almost 100 million metric tons of methanol are produced worldwide each year for a variety of purposes. Around 16 percent of this methanol is used as a fuel additive. However, as it is currently mainly produced using natural gas and coal, it hardly constitutes a win for the climate.

Alternative solutions are being explored in Niederaussem. For example, methanol is being made from carbon dioxide, a by-product of combustion – a technique which can also be applied to other power plants, waste incineration plants and industrial plants. This method of capturing and using CO2 – often referred to in Germany as CCU (Carbon Capture and Utilisation) – therefore uses greenhouse gas that would otherwise escape into the atmosphere without purpose.

Capturing and using CO2 in combination with renewable energy can therefore accomplish more than merely reducing carbon dioxide emissions - carbon dioxide itself is used as a raw material. Reinhold Elsen, Head of Research and Development at RWE Power

To turn carbon dioxide into methanol, it must first be enriched with hydrogen: H2 is obtained from water by electrolysis. Some of the electricity needed for this process already stems from renewables. The process is regarded as a promising method to overcome the dependency of wind and solar power on the weather. “Capturing and using CO2 in combination with renewable energy can therefore accomplish more than merely reducing carbon dioxide emissions,” stresses Reinhold Elsen, Head of Research and Development at RWE Power. “Through chemical conversion, electricity from regenerative sources can be stored over long periods of time, “and carbon dioxide itself is used as a raw material.”

Climate-neutral mobility

Many experts consider the production of synthetic fuels to be an important technological step towards making road traffic climate-neutral. However, e-mobility alone is unlikely to make this a reality within the given timeframe: For example, the EU has decided that truck traffic should reduce its emissions by 30 percent by 2030. At present, however, there are no practical rechargeable batteries, for heavy and long-distance traffic in particular. There is also a lack of suitable infrastructure – both for charging batteries and for refuelling hydrogen for vehicles with fuel cell drives. CCU fuels such as ethanol and methanol, on the other hand, can be distributed via existing infrastructures, i.e. normal petrol stations.

Virtually any conventional vehicle with a combustion engine can be powered by e-fuel and produce less emissions – whether passenger car or truck. One advantage of methanol over ethanol: consumable alcohol found in petrol is usually made from plants and therefore vie with food production for arable land.

Ultimately, the political agenda will be crucial to the economic success of this process. Reinhold Elsen, Head of Research and Development at RWE Power

Thanks to an improved catalyst, the new plant in Niederaussem produces up to one metric ton of methanol per day from 1.5 metric tons of carbon dioxide. However – as Reinhold Elsen points out – for now, methanol produced by carbon dioxide separation cannot compete in price with methanol produced from crude oil or natural gas: “Ultimately,” says Elsen, “the political agenda will be crucial to the economic success of this process.”