The coffee is brewing while the fried egg spits and sizzles next to the bacon in the pan. The students of the Eindhoven University of Technology (TU/e) are generating the electricity necessary for the meal themselves. But what sounds like basic physics is actually much more challenging. Instead of a wind turbine, a photovoltaic system or a steam turbine, they use iron powder to generate steam and electricity. They have developed the method themselves and claim that it is the only such process in the world.

The energy carrier of the future must meet multiple requirements. It must supply an enormous amount of energy, be accessible worldwide and be compatible with existing infrastructure. Iron power ticks all these boxes. Tim Spee, project leader of the metal power research project

The SOLID team is made up of 22 students from the Dutch university who have come together to work on the project. The name is derived from their common goal: to explore solid energy carrier and make them usable for industrial purposes.

“We are exploring iron powder because we desperately need a sustainable dense energy carrier that does not produce carbon dioxide,” says Wies Ruyters, a student in the SOLID team. Her colleague Tim Spee, project leader of the metal power research project, adds: “The energy carrier of the future must meet multiple requirements. It must supply an enormous amount of energy, be accessible worldwide and be compatible with existing infrastructure. Iron power ticks all these boxes.”

The technology, however, is still in its infancy. It currently generates 20 kilowatts (kW) of power in a single cycle, which is as much as a domestic boiler. Industrial applications would require at least 80 megawatts (MW) – 4,000 times as much. This summer, the process is expected to hit 100 kW.

“We want to show that the energy transition is achievable and that we can overcome today’s energy problems,” Ruyters affirms, and companies such as Shell and Uniper, two of a total of ten backers of the project, have been infected by this optimism. The North Brabant region is also subsidising the project, and in future the scientists will also be working at the local innovation and research centre Metalot.

Emission-free energy in a closed circuit

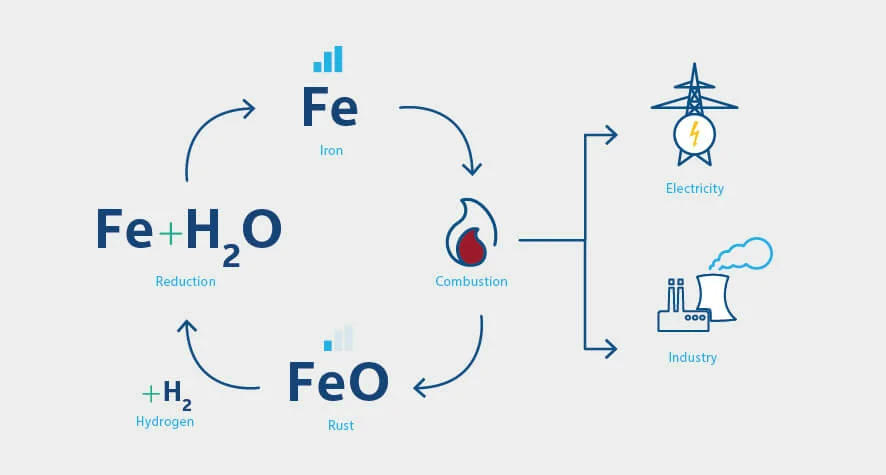

The students’ procedure works within a circuit: First iron powder burns in a flame and releases heat. Water vapour generated in this way can be used to generate electricity by means of a turbine. Iron oxide – also known as rust – is produced as a by-product and nothing more. The iron powder burns completely emission-free and can be almost completely reused, as Spee explains, “In the lab, we can filter well-nigh 100 percent of the ash produced and reuse it. In practical terms, 99.9 percent of the iron can be recycled with each cycle, depending on the filter technology used.”

The rust is then converted back to iron powder. Green hydrogen is used as an energy supplier for this process. What is referred to as the ‘reduction process’ sees oxygen separated from the iron and in turn bound with the hydrogen. The freshly prepared iron powder is then ready for the next cycle. This step also holds great potential for the energy transition, as the iron acts as an energy storage medium.

Iron powder stores renewable energy

The iron oxide no longer has any energy in it that could be used by burning. The reduction raises the energy level once more, so that thermal power can be released again. If renewables supply the necessary energy, it can be stored in the processed iron powder.

If iron powder is used within this circuit, it ticks all the boxes for the energy carrier of the future: it is easy to store and easier to transport than hydrogen, for example, and ties in with existing infrastructure. It could also serve as fuel for coal-fired power plants, thereby replacing coal in the long term. On top of which, it is one of the worlds most commonly available materials and is already being processed on a large scale in the steel industry, for example.

From making coffee to brewing beer

The system which was used to make coffee in the lab, will soon help to brew beer coming this summer. A brewery in Brabant wants to use the steam. The demonstration in the brewery signifies the end of the project for the time being: after this summers’ presentation, SOLID will be occupied by new team members that are motivated to take this technology further.

The next step is a plant with a capacity of one megawatt. Although the road to an output of 80 MW may be long, Spee remains confident: “It does not matter to what extent or in what way the technology will be used. There are so many possibilities, I’m confident iron powder will be used in some capacity to reduce carbon emissions.”