Solar expansion is an essential building block of a successful energy transition. To hit the German government’s target, the company plans to put 22 gigawatts (GW) of PV capacity on the system every year through to 2030. However, these assets often require major real estate, a rare commodity especially in densely populated areas. Researchers from the Karlsruhe Institute of Technology (KIT) are thus looking into how to improve solar panel efficiency with innovative technologies and artificial intelligence (AI).

As part of the Solar Farm 2.0 project, we want to explore how performance optimisers can make PV systems more efficient,” says Marcus Becker, Researcher at KIT’s Electrical Engineering Institute and member of the project team, summarising the undertaking.

The en:former has reported on various approaches that can be taken to make more efficient use of solar farms while reducing land use. Agri-PV is an example of how to make dual use of land to produce solar power and grow crops. Floating technology enables deployment of PV assets on bodies of water. Moreover, new materials such as perovskite promise to deliver efficiency gains. In solar farms where yield is curtailed through soiling, cleaning robots or drones can be the innovative solution, for instance in desert regions.

Tracking helps to optimise PV system output

Performance optimisers are already in use in a number of solar farms. They set the system‘s operating point to the maximum power point (MPP), where output is at its highest. The MPP depends on various factors that affect solar irradiation such as time of day, season, shade and soiling. These parameters change constantly, which is why performance optimisers constantly search for the MPP and regulate tension and current to ensure that the system delivers the maximum electrical output at all times. This is done using algorithms.

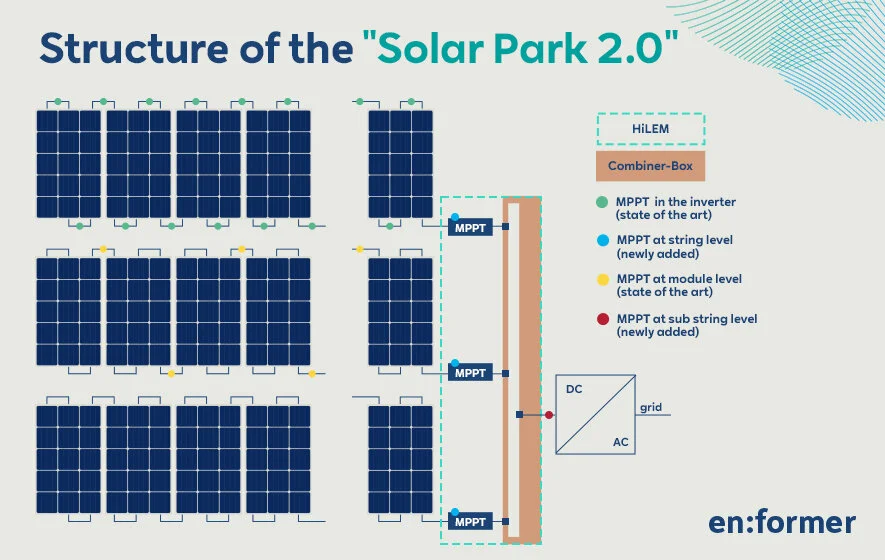

Current practice often entails deploying just one MPP tracker in the main inverter. However, various factors intermittently affect the modules of big systems in particular. An example is a farm only half of which is cast in shade by a cloud. This reveals the limitations of MPP tracking using a single performance optimiser. “Every solar module has its own MPP. This is why in our project, we want to deploy MPP trackers in strings, each of which encompasses several modules, and in individual solar modules as well. We expect to increase yield through granular tracking and matching optimisation,” declares Becker.

A ground-mounted PV system consists of a large number of solar modules. These are networked with cables to form strings. These strings are connected to a generator connection box (GCB) that bundles the electricity from all the cables in a DC main powerline. Then an inverter converts the direct current to alternate current, which can be fed into the grid.

Innovative switch enables granular MPP tracking

A project subsidised by the German Ministry for Economic Affairs and Climate Protection aims to use a novel switch developed at KIT. Dubbed ‘HiLEM’ (High Efficiency Low Effort MPP Tracker), the switch will replace the GCB used to switch PV strings in parallel thus far.

This will enable each string to be driven by a central inverter at its own MPP. In addition, the University of Karlsruhe, BRC-Solar and PREMA, all of which are project partners, are developing performance optimisers that can be installed in solar modules in order to enable MPP tracking down to the substring level.

These technologies will be the subject of a field trial as part of the project, which was launched in July 2022. To this end, an appropriate field trial will be prepared during 2023 once the hardware has been developed. Two 30-kilowatt peak (kWp) testing facilities will be built for this purpose on the premises of Energy Lab 2.0 at KIT. The HiLEM switch alongside the optimiser-equipped solar modules will be used in one of them, with the other serving as a point of reference.

Data from the field trial serve as a basis for AI engineering

One of the researchers‘ goals is to establish the efficiency enhancements achievable by optimising performance at the string and module levels as well as the technologies best suited to accomplish this.

Software solutions are not the only option. “Building on the data collected from the field trial, we want to develop an AI that is capable of creating performance forecasts for PV systems,” says Tim Kappler, researcher at ETI and expert for system solutions and analysis.

Based on the results of this assessment, recommendations will be issued, indicating where in the system efficiency can be improved through performance optimisers. To make reliable statements, the AI has to learn to assess various situations correctly. This requires the greatest possible data throughput. “For instance, the AI performance forecast must be able to distinguish between a module that is in the shade, has been soiled, or is defective. We will emulate these types of situations in the test facility and train an algorithm by feeding it this data,” explains Tim Kappler. To collect data, the KIT researchers use an innovative network of sensors that was developed by the Photovoltaics Institute of the University of Stuttgart.

The project has an initial duration of three years, during which hardware development, field trials as well as AI software programming and training will take place. The objective is for the findings to be applicable to as many systems as possible, thus paving the way for innovative, large-scale 2.0 solar farms.