Synthetic fuels can already be used to power vehicles with combustion engines in a climate-neutral way. These ‘e-fuels’ can help to reduce rising greenhouse gas emissions in the transport sector. And yet, until now, this type of fuel has only been produced in small batches in a select number of demonstration plants. In this edition of the Power-to-X series, en:former will be shedding some light on the reasons behind this modest production scale and will be looking into a number of power-to-liquid projects which are hell bent on using the technology in a much larger setting – thereby helping fulfil its heralded potential.

Being able to get into a completely bog-standard car, no matter whether gas or diesel-powered, start it, refuel it and drive it to another city – all without burdening the climate – is a concept that is more than a mere figment of imagination. The trick is to remove the carbon dioxide that is expelled into the air during the journey from the atmosphere or from another source, such as an industrial plant, ahead of time during the production of the fuel. This is where synthetic fuels come in, which are considered climate-neutral in this respect.

The miracle fuel doesn’t not look particularly exciting. The liquid is crystal clear, essentially odour-free, and its chemical structure and properties are no different from those of conventional petrol or diesel, which are obtained from crude oil. However, the proof is in the pudding: In addition to being climate-neutral, e-fuels boast a number of other advantages. For one, It would be possible to access them at gas station pumps, which means that – unlike with e-mobility – there is no need to develop new infrastructure. Another upside is that combustion releases significantly fewer other pollutants such as nitrous oxides. This is why the automotive industry, in particular, has high hopes for synthetic fuels (German only).

Sadly, e-fuels have not yet proven to be quite the breakthrough solution many had hoped for since only a few demonstration plants in Europe currently produce synthetic fuels, and in small quantities at that. The focus of these plants is very much on exploring and testing the technology and the processes employed. E-fuels are still a long way from market maturity and yet, the first production plants are slated for construction.

Well-known and repeatedly developed chemical processes are used in the production of synthetic fuels. As explained in detail in the previous part of the series, electricity from renewables, for example, is used to generate hydrogen in an electrolysis process and later converted to liquid fuel together with carbon dioxide. The term ‘power-to-liquid’ is the generic term for this type of process and pilot plants have successfully shown that power, water and carbon dioxide can be used to make fuel for cars, lorries, cargo ships and planes.

The Power-to-Liquid Technology

Introduction

The power-to-liquid technology uses green electricity to produce synthetic liquid fuels (e-fuels), which are considered to be climate-neutral. Click through the figure and learn more about the individual steps of the process.

Step 1: Renewables

Power-to-liquid technology uses electric energy to generate liquid energy sources. Or in other words: Power is turned into liquid fuel. In order for these synthetic fuels to help meet climate targets, the power used for this process needs to come from renewables.

Step 2: Electrolysis

Electrolysis produces hydrogen: Electricity is used to split water (H2O) into hydrogen (H2) and oxygen (O2). The oxygen is emitted into the air, whilst the hydrogen is used for the following steps.

Step 3: Conversion

In a two-stage process, carbon dioxide (CO2) and hydrogen are converted into hydrocarbon chains. First, carbon dioxide and hydrogen are reduced to carbon monoxide with water (H2O) as a by-product. The carbon monoxide is then combined with more hydrogen to form a synthesis gas. Various liquid hydrocarbons can then be produced from the synthesis gas using the Fischer-Tropsch process.

Step 4: Processing

The liquid energy sources can, for example, be processed in a refinery to make synthetic petrol, diesel or kerosene.

Step 5: Usage

Synthetic petrol, diesel or kerosene can be used to directly power cars, trucks, container ships or aircrafts. During combustion, the CO2 that was previously bound by the process is released once more. Furthermore, significantly fewer pollutants are emitted, compared to fossil fuels, as the products are purer.

In view of these advantages, the question that remains is, ‘What’s standing in the way of the success of this technology?’ The answer: Low efficiency and a steep price tag. Efficiency decreases because the individual process steps consume energy. This can be clearly seen when looking at the results of one study: According to a calculation by Agora Energiewende in 2017, a battery-powered car needs 15 kilowatt hours (KWh) of electricity, whereas a hydrogen-powered vehicle needs 31 KWh and an e-fuel-powered diesel or petrol engine requires a whopping 103 KWh. This means that more energy is needed for the same output. According to experts, electromobility is much more efficient than synthetic fuels when it comes to the passenger transport industry and is therefore the more popular solution.

However, electric vehicles cannot be used everywhere in the transport sector. “Aviation, shipping and heavy freight forwarding are areas that largely elude electrification,” explains Thomas Willner, Professor of Process Engineering at the Hamburg University of Applied Sciences (HAW). These sectors, in particular, are set to grow significantly on a global scale. He believes that alternative fuels are therefore indispensable for hitting climate targets. The German Energy Agency (dena) also emphasises the huge potential of synthetic fuels.

Another issue is that the low efficiency makes the fuel expensive. Especially in countries such as Germany, the plethora of taxes and levies is driving the price skywards. According to a study conducted by dena and Ludwig Bölköw Systemtechnik, a litre of diesel equivalent costs up to 4.50 euros. However, it is currently (as explained) not mass produced – which would help to significantly reduce costs. “E-fuels are still comparatively expensive, but the costs will continue to decrease. Even now, a number of these fuels are not far from being cost-effective,” explains Manfred Aigner, Director of the Institute of Combustion Technology at the German Aerospace Centre (DLR), in Handelsblatt (German only).

But synthetic fuels will probably remain more expensive in the future. According to a study conducted by the Wuppertal Institute for the Climate, Environment and Energy, the price per litre of petrol in fossil fuel form could be as much as 1.38 euros compared to 2.29 euros for the synthetic variant in 2030. Despite these hurdles, the first production plants are being planned and are set to go into operation in the coming years, which will continue to test the technology on a commercial scale.

Some exemplary projects in the overview

Out of all car manufacturers in Germany, Audi is the most invested in synthetic fuels. Some years ago now, the Ingolstadt car manufacturer launched a Lower Saxony-based power-to-gas (German only) plant, where power from renewables produces methane, which can be used to drive gas-powered cars. The next project by Audi is set to be much larger and will produce e-diesel instead of methane.

In the Swiss canton of Aargau, the Volkswagen subsidiary is planning a 1-megawatt pilot plant together with the German-Swiss energy supplier Energiedienst Holding and startup Ineratec GmbH. Plans envisage building the pilot directly next to a hydroelectric power station. The location offers a key advantage. The plant will use excess power from the power station and thus obtain electric power at virtually no cost. However, this also means that electricity cannot be produced around the clock, instead being limited to periods of increased power production.

According to Audi, the power-to-liquid plant will produce around 400,000 litres of e-diesel and waxes used in the chemical industry annually. The building application has been approved, and the company expects to be able to bring the first batches onto the market in 2020.

By contrast, Norway is operating on a whole other level. Nordic Blue Crude plans to construct a 20-megawatt plant in the Heroya industrial park on the south coast of the Scandinavian country by 2023. According to the company, the station will produce up to ten million litres, or 8,000 tonnes, of ‘e-crude’ every year. E-crude is a synthetic petroleum substitute, which means that it can be turned into products such as petrol, diesel or kerosene via downstream processes.

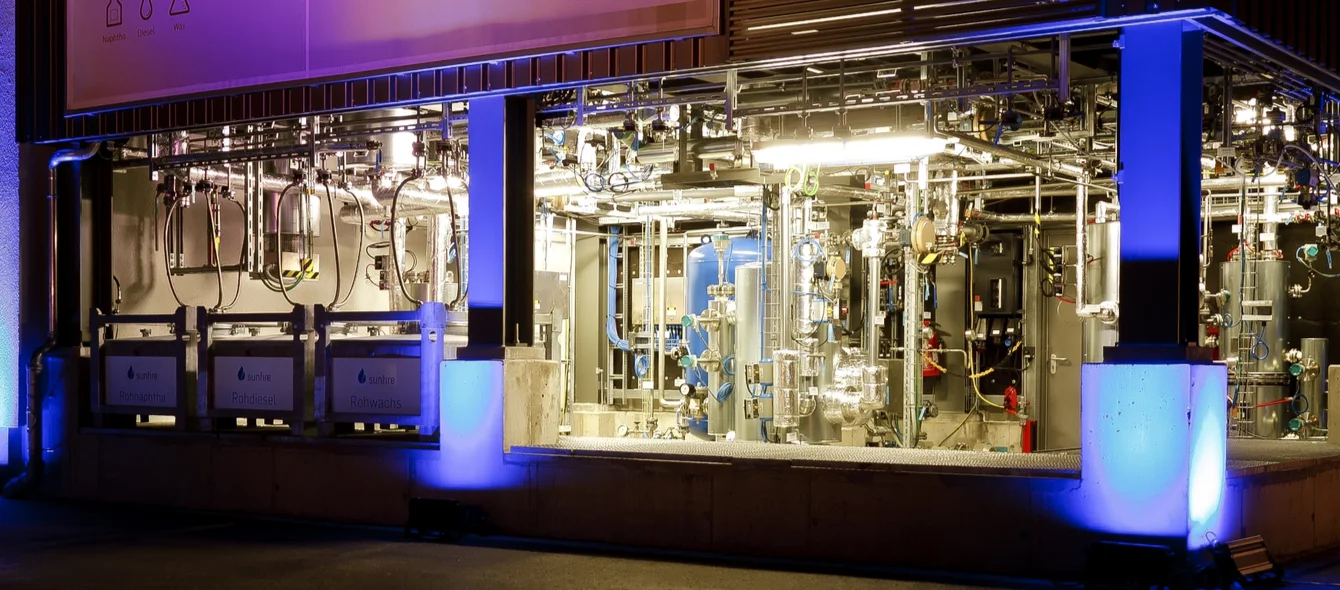

The Norwegian project is also relying on German support. Dresden-based Sunfire is considered to be one of the global pioneers of power-to-liquid technology. Launched in 2010 by three founders, the company has developed a three-stage process to produce synthetic fuels using green electricity. This is to be used in the plant in Norway. And, as with the Audi project, the electricity will come from hydropower, which is available there in large quantities and ensures low energy costs. The additional carbon dioxide required is to come both from the industrial park and directly from the air. According to media reports, the capacity of the plant is to be increased significantly at a later date. The project partners hope to reduce the currently high costs for synthetic fuels.

The phrase ‘flying shame’ says it all – aviation, in particular, is experiencing the brunt of climate protectors’ criticism. Aviation expands, emissions increase. The largest airlines in the world have set a self-imposed goal, to only expand CO2-neutrally (German only) moving forward. Since batteries are not usable alternatives for the foreseeable future due to their weight, interest in synthetic kerosene is growing.

In Lower Saxony, a power-to-liquid plant is to be built on an industrial scale. At least that’s what the partners, namely the Technical University of Hamburg, Airbus, BP, the German Aerospace Centre, Dow and Hoyer Logistik, are planning… The experts want to explore how PtL processes can be optimised from both an economic and ecological perspective. A plant based on Fischer-Tropsch synthesis is to be built on the site of the chemical company Dow in Stade for this purpose. The synthetic hydrocarbons produced there are to be supplied to the BP refinery in Lingen for downstream processing. The plans is to use them to manufacture kerosene.

Heide and the University of Bremen refineries are already up and running. The duo will use excess power from regional wind farms to produce synthetic kerosene and Lufthansa, the largest German airline, has come on board as a prospective buyer of the fuel.

In the “Power-to-X series”, the en:former presents technologies that convert electricity into other energy sources. In the upcoming weeks, the series will explain how power-to-heat works, how it can be used and its market potential. Another episode will focus on the possibility of advancing power-to-heat technologies.