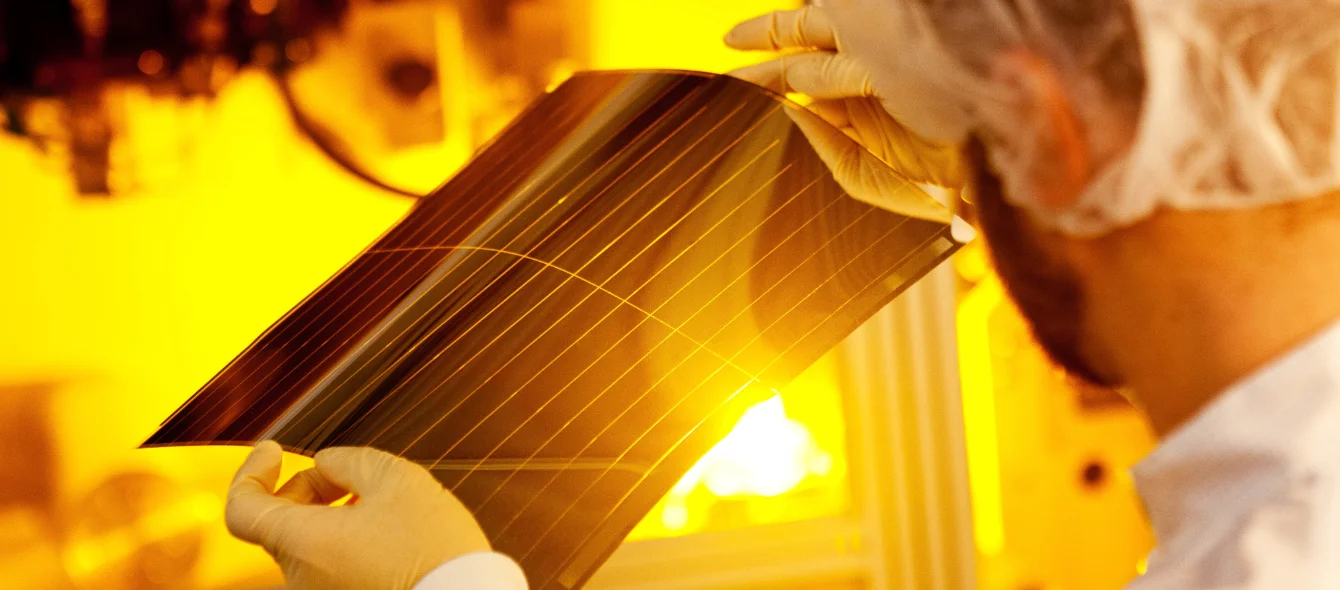

Windowpanes, warehouses and greenhouse films capable of using sunlight to generate electricity? Organic photovoltaics (OPV) makes it happen. For years now, the list of mounting sites for solar modules has been getting longer and longer – above all because they are becoming thinner and lighter. However, conventional PV cells made of silicon wafers do not stand a chance against OPV in this discipline. “A few nanometres of thin layers are all it takes to produce solar power,” says Birger Zimmermann, Team Leader Production Technology for Organic Solar Cells at the Fraunhofer Institute for Solar Energy Systems. “When it gets down to it, 99 percent of an OPV module consists of the carrier material.”

True to the diction of science, ‘organic’ in this context indicates that the product is ‘carbon-based’, meaning that the cells are made of plastic films instead of the (inorganic) silicon crystals used to date. The molecular structure unique to these plastic films lets them act as semiconductors, giving them the ability to convert light into electricity.

Efficiency with room for improvement

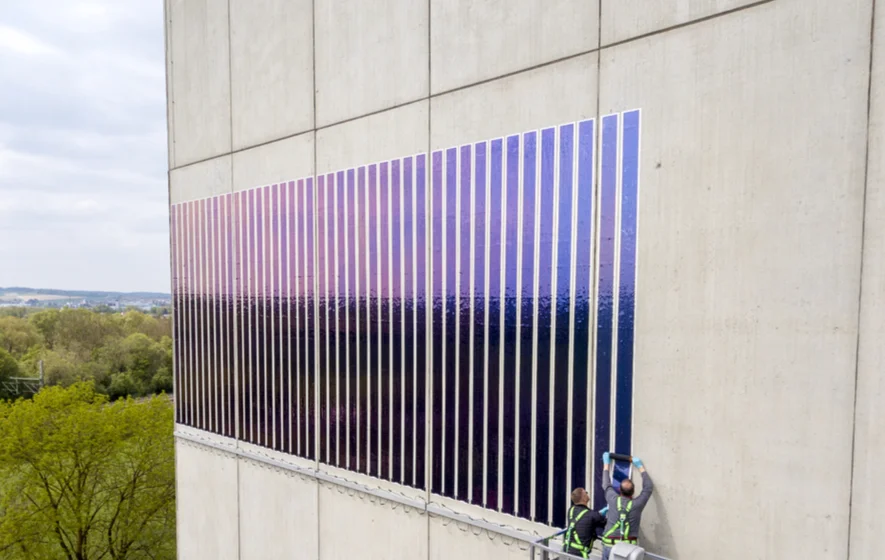

A host of companies already offers ready-for-use modules that are proving their worth in pilot projects. In Spain, OPV modules by Germany-based Heliatek have been fitted to the tower of a wind turbine. In South Korea, they are producing electricity on two sides of the facade of a Samsung building, while in the Port of Duisburg, Germany, they are doing likewise in a warehouse. One of the first such systems was mounted on a biogas plant back in 2016 by then-RWE subsidiary innogy. “The yield is very small, but encouragingly stable for a pilot,” says Claus Linnemann, who was involved in the project on behalf of innogy and is now a technical innovation partner at RWE Offshore Wind.

As so often with relatively young technologies, OPV has had a difficult time establishing itself on the market thus far. This is mainly due to efficiency. Current OPV modules convert around eight percent of the energy contained in sunlight into electricity. Monocrystalline silicon photovoltaics (SI-PV) achieve a score of over 20. “It’s already obvious that OPV modules with an efficiency of more than 15 percent are an absolutely realistic proposition,” declares Linnemann. And such efficiency levels have already been achieved in recent years, under laboratory conditions at least. However, other factors are the main arguments in favour of OPV. And these exist in abundance.

A film for every application

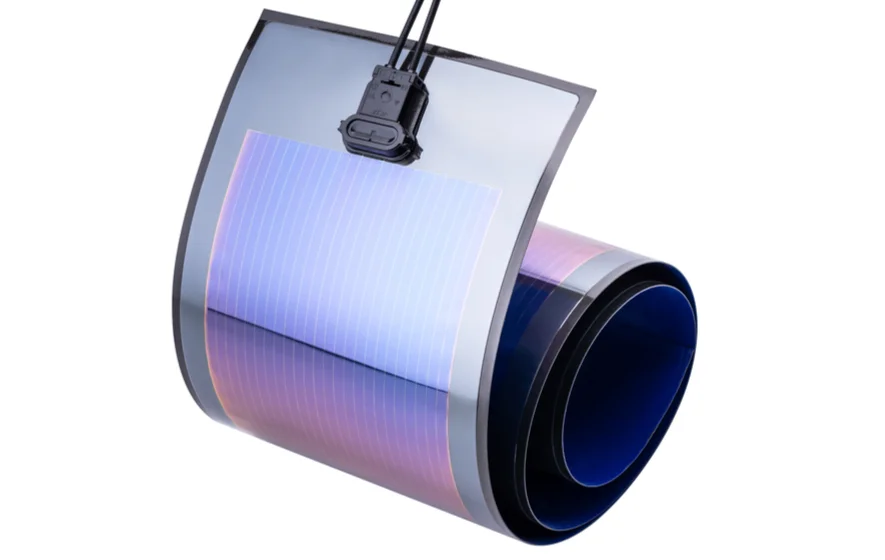

At Heliatek, for example, the focus rests on low weight and flexibility. The German firm manufactures complete OPV modules which, weighing in at about two kilogrammes per square metre, can basically be stuck wherever there is enough room and – ideally – significant exposure to sunlight. All that’s needed to make use of the electricity is an inverter.

“Our products can be applied to buildings incapable of bearing the weight of a conventional PV system,” explains Stephan Kube, Head of Marketing at Heliatek. OPV modules can be bent to a radius of 20 centimetres, making them mountable to street and traffic light posts.

Pilot projects from all across the world

PV modules for window panes

On top of this all, OPV has another, “truly unique” feature, emphasises Fraunhofer researcher Zimmermann: “OPV materials only absorb light in a specific spectral range. All other semiconductors absorb all the light starting at a certain energy level.”

This is the property on which US startup Ubiquitous Energy. has set its sights. The Californian tech firm manufactures power producing windowpanes. This involves applying a transparent OPV film directly to window glass. As set out by Zimmermann, the trick is that the films only use the invisible (infrared and ultraviolet) light spectrums to generate electricity. They largely let visible wavelengths through, giving the windows a slight tint.

Lower efficiency in exchange for transparency

“Figures show that this can still deliver efficiencies that are technically relevant,” says Zimmermann. People at Ubiquitous Energy hope that someday, up to ten percent of the sun’s energy can be converted to electricity by this method. The efficiency of transparent OPV modules will always fall short of that of variants such as the ones by Heliatek, which have a metallic rear wall that reflects light, thus doubling power production.

In very hot and sunny regions, the tint has a cooling effect, as it blocks some of the sun’s energy. Based on the company’s plans, such OPV systems would enable not just the windows of residential and commercial buildings to be used to generate electricity, but also entire greenhouses.

Does OPV supply more sustainable solar power?

Another, increasingly important, advantage lies in the material of OPV modules: “Organic photovoltaics will by far be the most environmentally and climate-friendly way of generating electricity,” says Zimmermann. Silicon, the metalloid forming the basis of conventional solar cells, is not a critical resource, as it is the most prevalent element in the earth’s crust after oxygen. Nevertheless, processing this substance to make solar cells is extremely energy-intensive. This is exacerbated by heavy metals which are used especially in thin film solar cells and have to be disposed of separately at the end of the cells’ lifetime.

OPV cells could theoretically be disposed of together with recyclable waste, says Zimmermann, and manufacturing them is much less energy-intensive, which translates into lower emissions and – potentially – lower cost. “Since OPV cell production has not reached industrial scale yet, prices are still very high. But once it has been fully scaled up and lessons have been learned in terms of material composition and production processes, OPV will most likely become much cheaper than SI-PV.”

Zimmermann believes that, in the final analysis, efficiency has to be improved in order to serve the mass market. This would enable OPV to be deployed extensively and, above all, where SI-PV is not an option. Anything else would make the space available for producing solar power even more scarce. Zimmermann is sure that “High-capacity OPV modules will be able to supplement established technologies, making a substantial contribution to electricity generation from renewables.”

Note from the editor: This article was updated in June 2024.