Building an offshore wind farm is no easy feat, but keeping it running to generate clean, sustainable energy over the long term also presents major challenges. According to the paper Operation and Maintenance Costs of Offshore Wind Farms, published in April 2017, these expenses represent 25-30% of a wind farm’s total lifecycle costs. Wind farms are steadily being built further from shore and in deeper waters with larger turbines. This generally means harsher sea and weather conditions, which requires a strict safety regime for hazardous offshore operations. Often the window of opportunity for repair provided by the weather is small, the cost of specialised vessels, equipment and personnel high, while an out-of-operation turbine means lower revenues and less clean energy.

That’s why the Multi-Platform Inspection, Maintenance and Repair in Extreme Environments (MIMRee) project is seeking to develop the world’s first fully autonomous inspection and repair system. The aim is to find smarter and safer ways of effecting repairs in ever more extreme environments. The project spans a range of cutting edge technologies from robotics, artificial intelligence, marine and aerial engineering to space mission planning.

Robot bugs

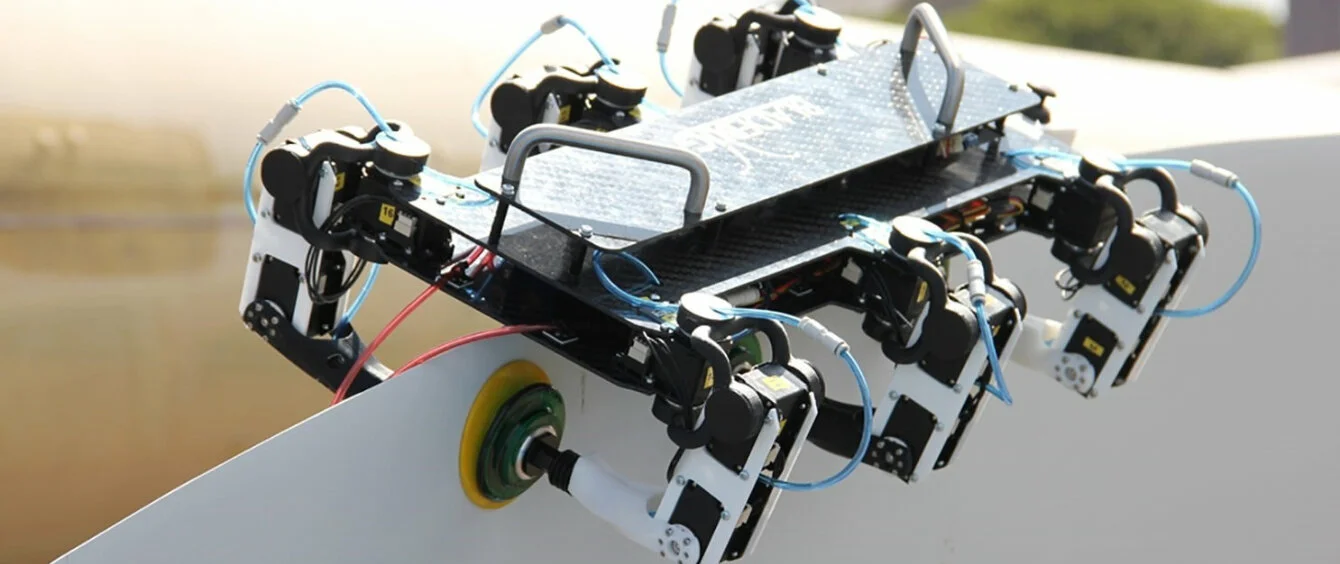

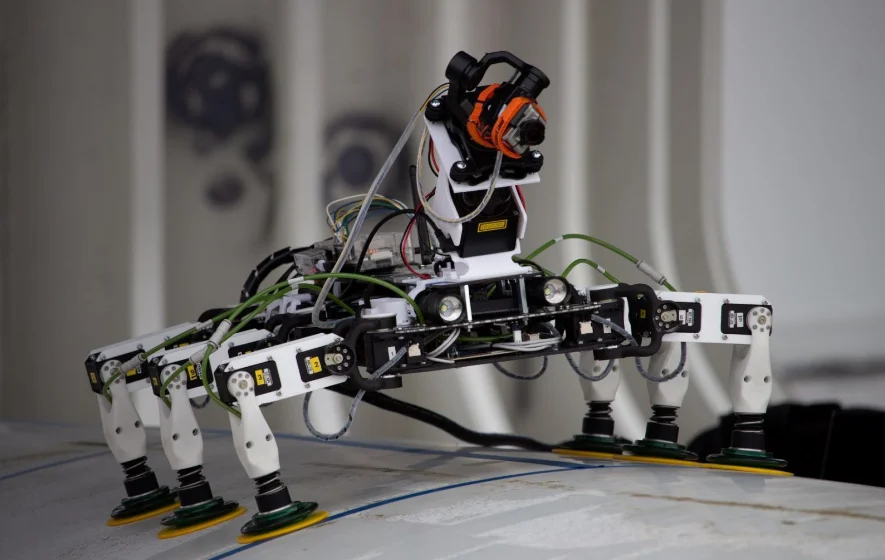

The idea is that drones will be launched from an autonomous mothership and conduct a visual inspection of the wind turbine blades. Once an assessment has been made and a problem identified, the drones transport robots up on to the blades. These six-legged creatures fasten themselves to the blade surface using a novel adhesion technology, developed by start-up company Bladebug, which allows the robot to crawl along the surface of the turbine blade.

The robot bug uses a hyper-spectral camera to analyse the chemical composition of the blade surface to see if surface wear is causing a problem. Once a problem is identified, the semi-autonomous bug will be able to carry out the repair itself using a special robotic arm developed by the Royal College of Art’s Robotics Laboratory. The robot moves by lifting three of its feet forward at a time, while the other three remain firmly adhered to the surface. Once deployed, the robot, which will be able to carry different types of testing and repair equipment, will continue to work even when the wind is too strong for drones.

A key advantage is that, in combination with the drones, the bug takes technicians out of dangerous situations. It can also intervene earlier than a traditional rope access team — early intervention maximises asset lifetime.

How the BladeBUG technology works (in English)

Field trials this year

It might sound like science fiction but the project, which has received two tranches of funding from Innovate UK, is in its second phase. Phase one produced a robot capable of securely gripping all parts of the wind turbine blade. Phase two is expected to see live trials this year of the bug’s test and repair capabilities.

Meanwhile, technology company Thales has developed an autonomous vessel, Halycon, and the University of Bristol are working on specialized drones, all of which could add up to a fully autonomous test and repair system for harsh offshore environments.

Offshore wind costs have fallen substantially in recent years and employing cutting edge technologies will allow the sector to continue to bear down on costs, not only making renewable energy ever cheaper, but expanding the areas in which offshore wind farms can be sited. Cost modelling suggests the robot bugs could reduce blade maintenance costs by 30%, compared with traditional methods. According to MIMRee, the technology could save the average wind farm £26 million over the course of its lifetime.

Photo credit: © BladeBUG