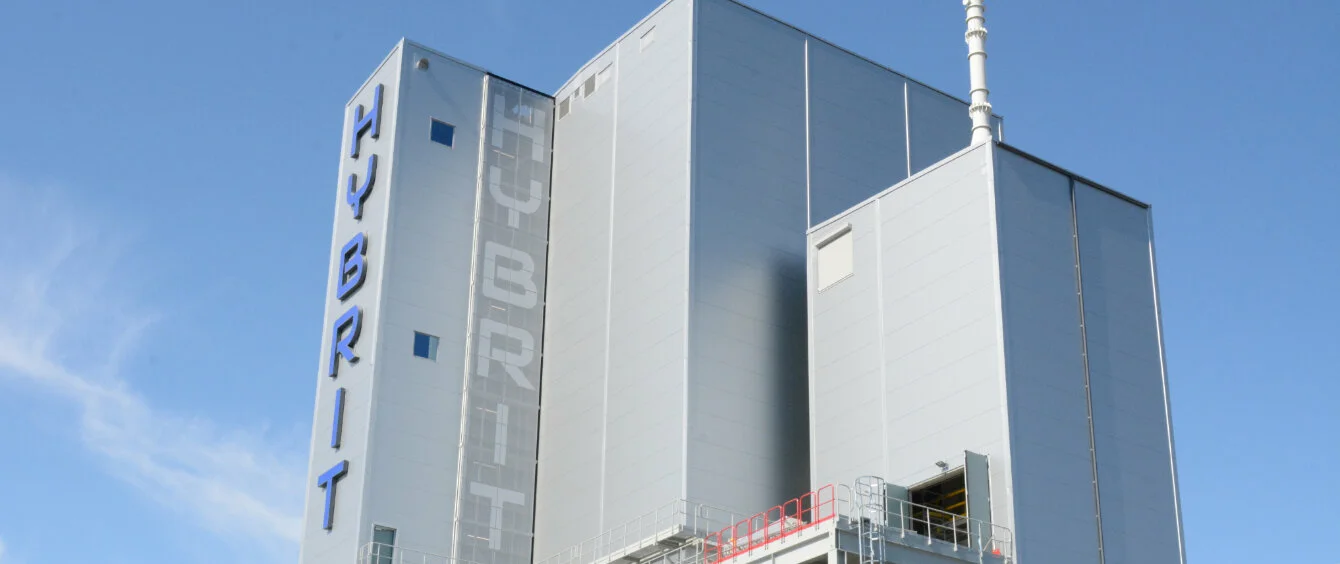

Swedish joint venture HYBRIT has taken a major step towards producing steel without emitting carbon dioxide. Two years after turning the sod in Luleå the project partners – steel producer SSAB, iron ore producer LKAB and power producer Vattenfall – commissioned a test facility in northern Sweden. The plant extracts iron from iron ore without using coal, thus significantly reducing carbon dioxide emissions.

Accounting for seven percent of global carbon dioxide emissions, the steel sector is one of the biggest polluters bar none. The blast furnaces consume enormous amounts of fossil energy to reach the required temperatures. This is compounded by conventional steel production releasing carbon dioxide due to the process employed.

Steel companies have long been investigating how to reduce process emissions. The solution, which is being worked on by German industrial giants such as Thyssenkrupp and Salzgitter in addition to HYBRIT, is termed ‘hydrogen direct reduction’. This involves extracting carbon from iron ore using hydrogen instead of coal. As a result, carbon dioxide is replaced by water vapour as waste gas.

HYBRIT has begun operating such a hydrogen direct reduction plant. The JV plans to obtain the required energy from renewables. In addition, the hydrogen used is to be produced in a carbon-neutral electrolyser, enabling the entire production process to be free of greenhouse gases. Industry-scale production is envisaged to start in 2035.

Photo credit: HYBRIT