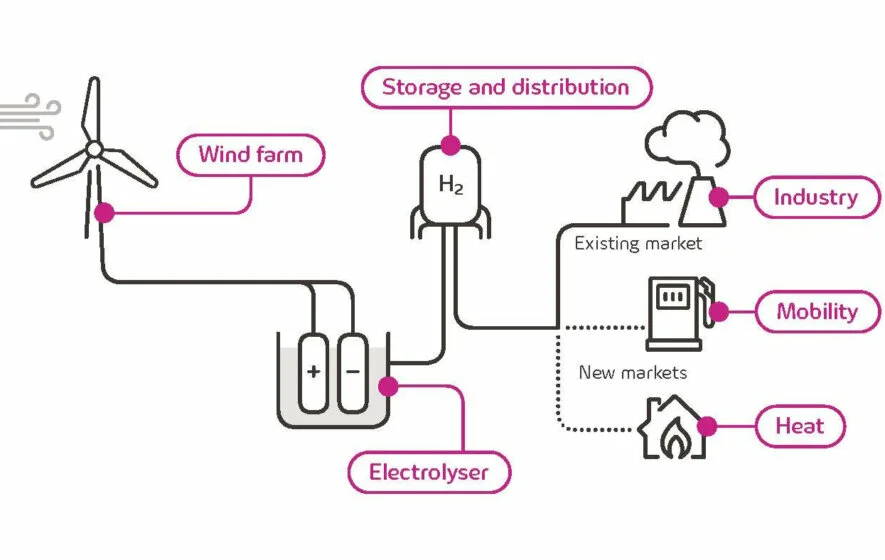

The concept has captivated many in the energy sector: powering hydrogen plants with wind farms. Electricity produced by these regenerative means could be used in electrolysis to obtain climate-neutral, green hydrogen. In turn, this hydrogen could replace fossil fuels and raw materials in transport, heating and Industry to contribute to reducing greenhouse gas emissions and hitting Europe’s and the world’s ambitions climate targets.

Industrial Power-to-Gas plant feasibility study

In light of the potential harboured by green hydrogen, Power-to-Gas technology (conversion of electricity to gas) is the subject of intense debate in many European countries, including the Netherlands. New findings come courtesy of an industrial-scale green hydrogen production trial in the Dutch province of Groningen.

Energy companies RWE and innogy launched a feasibility study for a 100 megawatt Power-to-Gas facility at Eemshaven. To be more precise: for the construction of a plant on the premises of the RWE power station. A key locational factor is innogy’s Westereems wind farm consisting of 52 turbines, making it one of the largest onshore wind farms in the Netherlands. Westereem could supply the electricity needed for electrolysis. This would enable wind energy to be harnessed to produce vast amounts of green hydrogen.

Green hydrogen – a major building block

“The CO2 reduction goals in transport, heating and industry can only be achieved by spurring sector coupling, resulting in the use of zero-emission energy sources. We’re convinced that green hydrogen will be a key building block of the clean and secure supply of energy in these sectors,” declared Roger Miesen, CEO of RWE Generation SE, commenting on the start of the feasibility study.

Hans Bünting, COO Renewables at innogy SE, cited further reasons for the companies’ intention to check industrial plants for feasibility: “We firmly believe that it is better to explore converting electricity to hydrogen as a technical solution taking the Power-to-X approach now than to play the waiting game. It’s important to collect practical experience.” The Westereems wind farm would be perfectly suited as a demonstration project of this size. Moreover, the site has additional advantages: the Eemshaven power station produces desalinated water which can be used in electrolysis.

Taking stock: green hydrogen must be priced

The feasibility study was conducted by RWE and innogy personnel in cooperation with the GetH2 project team in the Lower Saxon town of Lingen, which engineers Power-to-Gas applications. The first results were obtained at the end of 2019, about three months into the project.

Electrolysers with capacities varying from 20 to 100 MW are being examined. Furthermore, the plant’s potential configurations – e.g. sourcing power exclusively from the wind farm or covering a portion of the power requirement from the grid – will be determined by legal framework conditions. However, one of the first of the study’s findings is that the hydrogen plant should have a capacity smaller than that of the wind farm as wind turbine arrays rarely deliver their maximum output. Therefore, it would not be efficient to connect a 100 MW facility to a 100 MW wind farm since a hydrogen plant should run for far more hours under full load.

The study is also looking into the commercial viability of such a facility. The conclusion is that an industrial-scale production plant would have to be subsidised until the market paid a premium for green hydrogen. At present, hydrogen obtained from fossil fuels is much cheaper to produce. Various approaches are being explored in the study. For instance, consumers could be legally obligated to have green hydrogen account for a certain portion of the fuel they use, similar to the blending rate for E10 petrol. A quota would create demand – and in turn a price – for the climate-neutrally produced gas. Similar ideas are being considered in relation to synthetic kerosene, which can be obtained using Power-to-Liquid methods.

Climate-neutral aviation with wind and biomass

RWE and innogy are in talks with potential buyers to determine whether there is an interest in green hydrogen at an appropriate price. It is also envisaged to enter into dialogue with policymakers to discuss ways to subsidise this type of project.

The long-term vision is for the Eemshaven power station to be gradually converted to fire biomass. The carbon dioxide resulting from the combustion process could be captured via CCS and used as a raw material to produce electricity-based, climate-neutral fuels. Wind and biomass could be used to ensure that aircraft and lorries go on climate-neutral journeys in the future.

Photo credit: innogy SE