Petrol and diesel are used to power cars and trucks, gas and heating oil are used for heating. Ultimately, both the transport and heat supply industry are heavily dependent on fossil fuels and belch far too much carbon dioxide into the atmosphere. One possible method to supply these sectors with power in a climate-neutral way could be to convert renewable electricity into gas, liquid fuels or heat. In the second part of the ‘Power-to-X’ series, we will be looking at ‘Power-to-Gas’ technology, examining just how it works and exploring its potential.

It sounds contradictory: storms in autumn making for a warm and comfortable home. But that’s exactly what is happening in Ibbenbüren in Münsterland. If the local wind farm generates more electricity than can be purchased locally, the surplus is used to produce hydrogen. This gas is then fed into the grid and used to heat the apartments and houses of the local population.

The project near Osnabrück is one of more than 20 research and pilot plants in Germany, which use and develop what are known as Power-to-Gas technologies. Electricity from renewable energy is converted into gas through chemical processes and the fuel generated in this way can be used to drive vehicles and heat houses. The big advantage is that renewable energy can increasingly be used within the transport and heat supply industries, without being forced to replace the entire vehicle fleet and most heating systems, to boot. In addition, unlike electricity, gas can also be stored on a large scale over the long term without suffering major losses.

Power-to-Gas is therefore regarded as an integral technology to hit energy and climate targets, which is being researched and developed, but has, thus far, not been made available commercially.

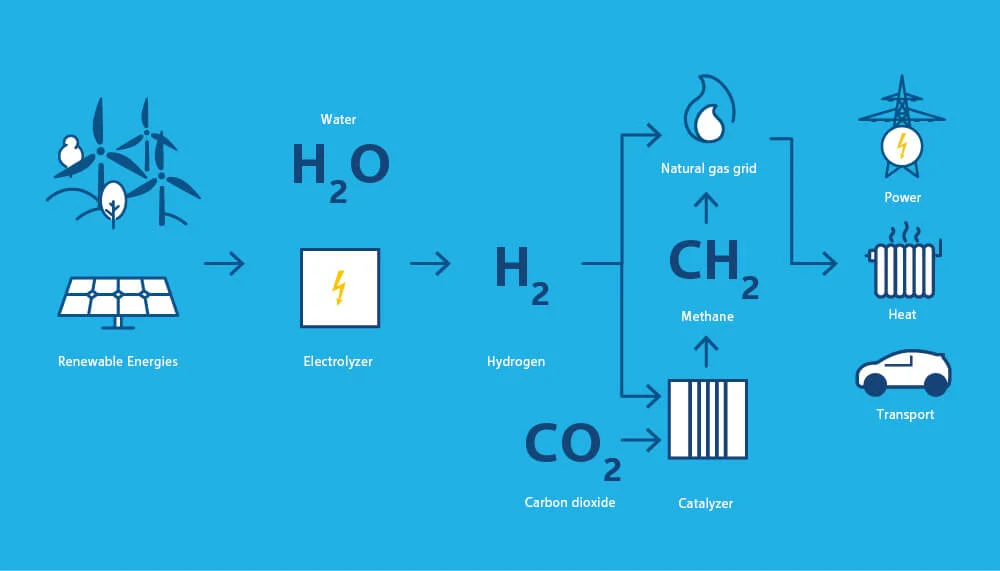

Electricity turns water into Hydrogen

The process on which the technology is based – electrolysis – has been around since the 19th century. An electrolyser is used to decompose water into hydrogen and oxygen by means of electricity. The hydrogen obtained in this way can be used as an energy carrier in fuel cells to power vehicles, for example, or is sought after in the chemical industry. Another option is to convert hydrogen to synthetic methane by using single-celled organisms called ‘archaea’ together with carbon dioxide. The resulting fuel is chemically identical to natural gas and can then be fed into the gas grid.

The Power-to-Gas demonstration plant in Ibbenbüren, operated by energy supplier innogy, produces hydrogen. If the local grid operator Westnetz records an oversupply of electricity from nearby wind power or PV plants, then electricity is fed into the electrolyser. “Rather than take wind turbines off the grid, we can actually use the surplus energy,” says Philipp Werdelmann, Head of New Technology at innogy. The plant, with an input line of 150 kilowatts, can produce 30 cubic meters of hydrogen per hour. The gas produced in this way is then fed into the local grid, albeit with a maximum hydrogen content of two percent or less within the natural gas grid. The hydrogen, produced from green electricity, is used to heat houses and apartments in the region or is then used to generate electricity and heat in a neighbouring CHP plant. In doing so, less natural gas is burned and carbon emissions are cut.

Gas grid and caverns as storage

“Power-to-Gas is the only technology that is currently available which enables both long-term storage of renewable electricity whilst also making it available to all other energy consumption sectors,” writes the German energy agency, dena, in its report “Power to Gas Potentiality Atlas”. Methane produced with green electricity can theoretically be input into the entire gas network, spanning more than 500,000 kilometres, and can be stored in any of the approximately 50 underground storage facilities. It can also be easily transported via the network without any relevant losses.

However, although the technology is already available, it has thus far been used exclusively for research purposes. dena’s Power-to-Gas strategy platform lists more than 20 pilot and test plants in Germany, which together have an installed electrolysis capacity of 20 megawatts (MW). Both start-ups and large energy suppliers are testing new processes, components and operating concepts. “Germany is currently playing a pioneering role in the testing and further development of Power-to-Gas technologies,” dena explains.

High costs and conversion losses

However, marketable applications do not (yet) exist. The problem is that the costs are simply too high, making its operation uneconomical. According to a study by the Energy Brainpool analysis institute on behalf of Greenpeace Energy, producing hydrogen with Power-to-Gas technology currently costs around 18 cents per kilowatt hour (ct/kWh). Yet levies from the Renewable Energy Act together with grid charges make prices rise to up to 38 ct/kWh, which is considerably higher than the price of natural gas clocking in at around 2 ct/kWh. Even if the price were to fall considerably due to larger production volumes, experts estimate that it will take at least until 2030 before the technology is able to hold its own.

One reason for the high costs are large conversion losses. Electrolysis alone generally consumes around 30 percent of the energy fed into the grid. One kilowatt hour of electricity thus becomes 700 watt hours of hydrogen. After methanation, even less usable energy is left. The consulting firm Front Economics has carried out a study, on behalf of Agora Verkehrswende and Agora Energiewende, to calculate the efficiency of Power-to-Gas technology applications: While an electric car uses almost 70 percent of the electricity, a fuel cell car, which runs on synthetic hydrogen, only uses around a quarter. Things are similar when it comes to heating: synthetic methane only uses around half of the electricity generated by wind or solar power plants. Using renewable electricity directly in electric vehicles as well as electric heat pumps for heating is therefore much more efficient.

According to dena, in light of high costs and conversion losses, Power-to-Gas should only be used “where there are no technological alternatives and it is not possible to use renewable energy directly. Power-to-Gas can, for example, provide low-emission fuels for heavy goods vehicles, ships and air traffic, where electric mobility is not possible due to the distances which must be travelled and the increased weight of the batteries. The technology could also function as seasonal energy storage if very high levels of green energy are generated moving forward. Excess wind power can thus help to cover peaks in heating demand in winter.

That's how electricity from renewables can be used in the transport and heating sector

Larger plants are in the pipeline

The technology is being tested and developed in research and pilot plants. One of the goals in Ibbenbüren is to increase efficiency. Innogy is investing in an innovative electrolysis process that converts the applied current more effectively whilst also being able to react quickly to load fluctuations. Another step: “We also use the resulting waste heat, thereby achieving a higher capacity factor than other plants,” explains innogy manager Werdelmann. When producing hydrogen, a portion of the waste heat generated by the electrolyser is used as process heat next door. And if the CHP unit uses the gas to generate electricity, the resulting heat is fed into the local district heating network. In this way, a capacity factor of up to 75 percent can be achieved. Since its launch in August 2015, the plant has been in operation for around 7,500 hours. In one given year, it is possible to produce around 170 megawatt hours (MWh) of hydrogen and then feed it into the grid, for example. In comparison, the average annual gas consumption of a detached house is 23 MWh.

Much larger test plants are currently in the pipeline. The gas and electricity network operators Tennet, Gasunie and Thyssengas intend to build a 100 megawatt (MW) plant in East Frisia. The project will kick off with a first module in 2022, followed by the construction of a new module every other year until 2028. Grid operators Amprion (electricity) and Open Grid (gas) are planning a demonstration plant with a capacity of 50 to 100 MW, which is to cost between 100 and 150 million euros. Locations in Lower Saxony and upper North Rhine-Westphalia are also on the cards. Klaus Kleinekorte, Technical Director of Amprion, told Handelsblatt, “Applying this technology on an industrial scale has not yet been put into practice. However, this will become ever-more important in the coming years”.

Power-to-X series in en:former

In the ‘Power-to-X’ series, en:former presents technologies that convert electricity into other energy sources. In the coming weeks, the series will look at how Power-to-Liquid and Power-to-Heat technologies work, their applications and market potential.